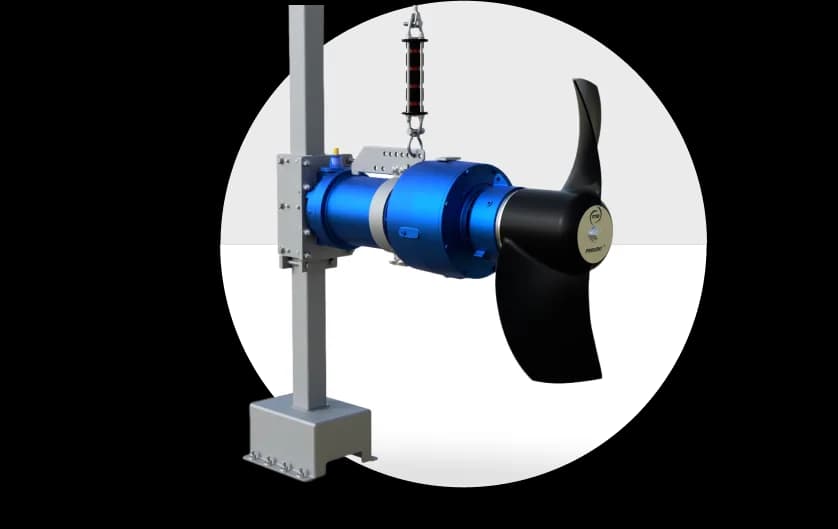

It is the most efficient mixer type for biogas applications where turbulence production is required together with high thrust power.

Phantom 1000 is mainly used to mix the substrate, destroy or prevent floating layers and also break sinking layers.

Thanks to its special impeller design, it not only provides high mixing rates, but also has a patented design that prevents material from getting tangled on the mixer impeller, thanks to the cutter mechanism behind the impeller.

3D Polyamide Propeller “3 Years 100% warranty” long-lasting usage opportunity

5700-7800 (volume) volume mixing possibility

11 tons propeller breakage resistance creating high turbulence at low rpm thanks to the patented special propeller design)

Special seal system unique cable feeding

TECHNICIAL SPECIFICATIONS

| Propeller Material | Physinit® |

Propeller Diameter | 1000mm |

Propeller Speed | 157 - 184 rpm |

Axial Thrust Force | 5000N |

Energy Efficiency Class | IE3 |

Explosion Protection Zone | II 2G Ex db h IIB T3Gb |

Motor power | 11 - 16 kW |

Operating temperature | 60°C |

PHANTOM

The Only Manufacturer Providing 100% 3 Year Warranty

Non-melting Patented Polyamide

Single Mixer with Propeller

Unrivaled in Waste Acceptance Tanks

Single Mixer Model that Reduces Internal Consumption by 15-30%

The Only Mixer That Can Cut

Fiber Materials on the Propeller

1000 mm Propeller Diameter