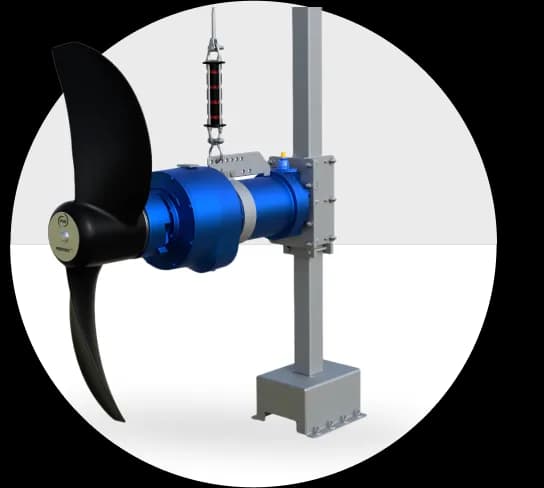

The Phantom 1400 is a hybrid mixer model for biogas applications that fills the hydraulic gap between the slow-running Phantom 2500 and the faster-running Phantom 1000. Therefore, thanks to its high thrust forces, it can contribute to the formation of a global tank flow in biogas plants.

At the same time, the impeller, designed by hydraulic experts, also produces the turbulences necessary to prevent floating layers. This mixer is extremely versatile across a wide range of applications. For example, fast mixers with motors up to 18.5 kW can be replaced by a Phantom 1400 with a nominal output of 7.5 kW without losses of thrust, allowing energy costs to be reduced by up to 60%.

Since the Phantom 1400 acts as a flow accelerator as well as a source of turbulence with lower energy consumption, fermenters can also be used as a single mixer, for example in 75kW biogas plants.

TECHNICIAL SPECIFICATIONS

| Propeller Material | Physinit® |

Propeller Diameter | 1400mm |

Propeller Speed | 88- 115rpm |

Axial Thrust Force | 5800N - 7000N |

Energy Efficiency Class | IE3 |

Explosion Protection Zone | II 2G Ex db h IIB T3Gb |

Motor power | 11 - 16 kW |

Operating temperature | 60°C |

PHANTOM

The Only Manufacturer Providing 100% 3 Year Warranty

Non-melting Patented Polyamide

Single Mixer with Propeller

The only system that can mix 9000 Volume at 112 rpm

Opportunity to Reduce Domestic Consumption by 20-60%

The Only Mixer That Can Cut

Fiber Materials on the Propeller

1400 mm Propeller Diameter